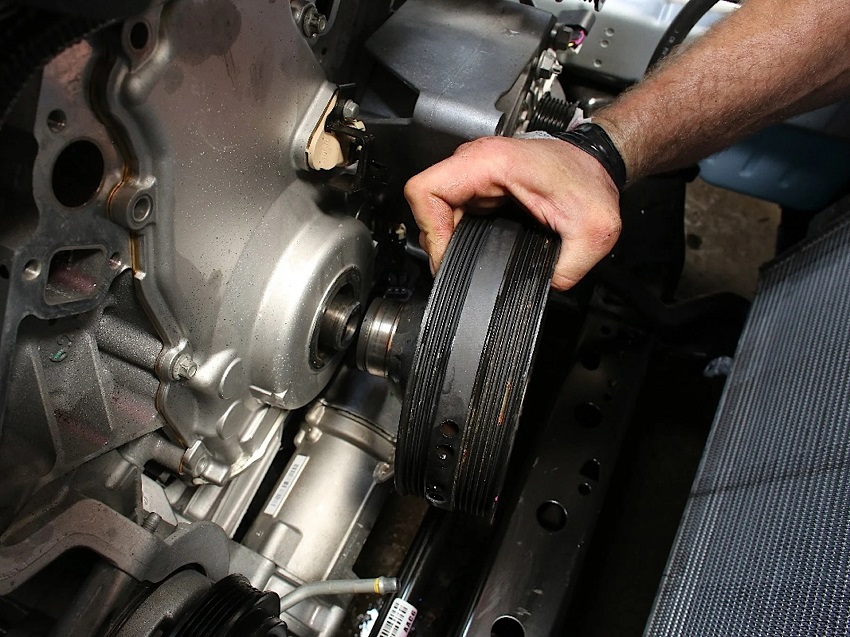

Located at the front of the engine, and attached to the crankshaft is the harmonic balancer. It goes by different names, including crankshaft pulley or harmonic damper. It is tasked to balance the different forces acting on the crankshaft as it spins. The faster the engine speeds, the stronger these forces become. That’s why a high-quality harmonic balance is a necessity on performance engines. Without one, the engine will tear itself apart.

Engine Harmonics

Engine harmonics refers to the different types of vibrations produced in the crankshaft and all connected parts (and there are many). These can be unbalanced vibrations caused by mix-matching pistons, connecting rods and the crankshaft counterweights. Axial vibrations are the front to back movement of the crankshaft in the crankcase. These are countered by the thrust bearings and main bearing support plate. What is harder to control are torsional vibrations. This is the end-to-end twisting and subsequent rebounding of the crankshaft during the different strokes. As the crank completes one rotation, the pistons act on the connecting rods sitting along the crank journals. The crank spins, but also twists. As the pistons move up the cylinder bore, the crankshaft rebounds to its initial position. The effect is multiplied by pistons pushing down in different cylinders, and exerting a push-pull force along the length of the crankshaft. Vibrations increase with RPMs.

The Role of Harmonic Balancers

To quell excessive vibrations cars with performance in mind have an engine harmonic balancer. The role of the harmonic balancer, or more correctly, damper, is to reduce torsional vibrations to a tolerable level. The front pulley also has additional systems connected, like timing belts controlling the camshafts and valvetrain, the oil pump, as well as the air-con. A damaged or underperforming harmonic balancer will cause hastened parts wear. Main journal bearings, camshaft lobes, valves and valve springs, the timing belt or chain, and the air conditioning belt are all affected. Damage to any of the parts here, especially with the timing belt or oil pump can seize the engine.

Another major concern is resonance. This occurs when the normal frequency of the rotating crank coincides with that of the torsional vibrations. This happens at a specified RPM, and if allowed to go on for longer, can result in a significant spike in vibration amplitude. An exponential increase in vibrations can snap a crankshaft in half, taking with it everything that is connected as collateral damage.

Also, consider the power loss if vibrations aren’t controlled. An engine harmonic balancer that performs its task will minimise torsional vibration and its effects. A balanced engine, and one that is not hindered to spin freely at higher speeds, will also produce more torque and horsepower. The added weight of several hundred grams of the harmonic balancer might go against the trend of making everything lighter, but pays off in droves.

Types of Harmonic Balancers

Three types of harmonic balances are found in cars. Stock engines make do with a rubber balancer, while performance and upgraded engines will benefit more from viscous/fluid balancers or clutch-type balancers.

Rubber or elastomer balancers have rubber O-rings fitted between an inner and outer shell, and the assembly is connected to the crank via a bolt-on metal hub. The thickness and hardness of the rubber will determine how the increases in vibrations are dampened and controlled. This is the simplest form of harmonic balancer, yet when specified in better designs and tougher materials can provide some performance gains.

When changing the engine internals that up torque (and vibrations), a good choice is a fluid or viscous harmonic damper. This consists of three major parts. The outer housing connects to the crankshaft. With the torsional vibrations created in each power stroke, the outer housing spins out of phase in relation to the inner inertia ring. What separates the two parts is the shear gap, filled with silicone. This creates shear as the vibrations and RPMs increase, effectively turning the rise in pressure into heat that oozes out of the outer ring. The benefit of a viscous or silicone balancer is that it is more effective through a broader rev range.

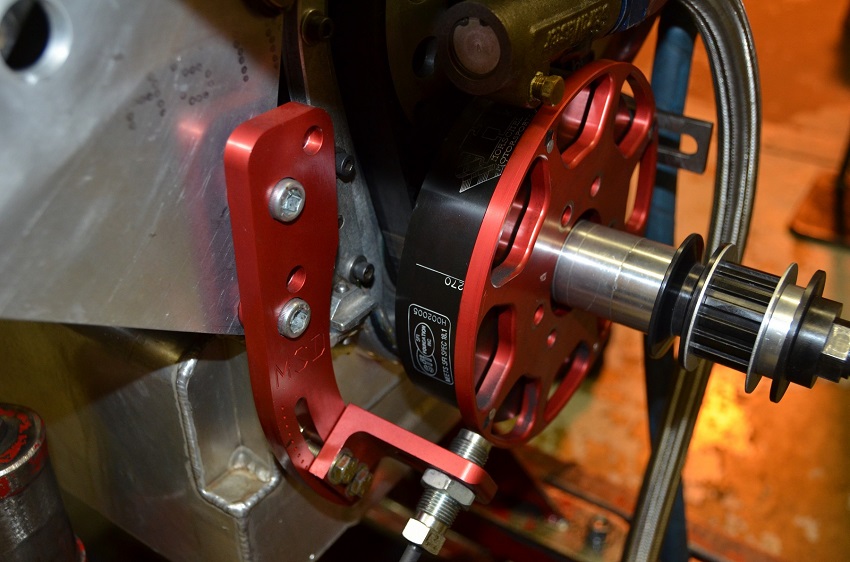

Lastly, there are clutch or friction type balancers. These have a set of internal spring-loaded clutch discs, set around outer inertia rings. The discs can be tuned to absorb and dampen vibrations at different rev ranges, so can compete with silicone dampers in high-performance engine builds.

Why You Need a Harmonic Balancer?

An engine harmonic balancer performs three functions well. First, it reduces the resulting torsional vibrations during each rotation of the crankshaft, and more so as engine speeds increase. Uprated harmonic balancers are therefore more in line with the upgrades in engines tuned to spin faster. Next, the dampening effect protects all other connected parts besides the crankshaft. A damaged stock damper that doesn’t work as intended, can cause damage to main bearings, connecting rod bolts, valve springs, timing belts and the flywheel. There’ll be misfiring and problems changing gears among other issues. Lastly, the balancer helps retain power that otherwise would be lost in increased engine vibration. Engines can spin freely as a result.

Choosing the right harmonic balancer largely depends on what you intend to do with the engine. If this is a stock engine without any modifications, then a worn or damaged elastomer balancer is cheap to replace. If you want more torque and horsepower when doing an engine rebuild, then consider getting either a silicone fluid balancer or clutch balancer in the appropriate diameter and weight.