Unless you’ve spent the last 70-or-so years in blissful slumber, then you’re undoubtedly familiar with hook and loop style, reclosable touch fasteners. Used to bundle, wrap, and fasten everything, from computer cables and medical tubing, to laceless sneakers and sanding pad backings, they may be as ubiquitous as scotch tape. But they aren’t without a hefty share of sticking points. No pun intended!

Given their tendency for snagging onto anything they possibly can (usually if you don’t want), and refusal to line up perfectly to ensure they’ve been fully engaged (especially if you do want); it could just as well be argued that their universal acceptance may only be tied to the fact that nothing better’s ever come along. That is, until now.

The better, reclosable fastener

The great flaw with hook and loop style fasteners is in the design itself: the embedding of tiny hooks into even tinier loops to form a bond. The dilemma is that once those hooks become elongated, almost any manner of fibrous-like filament will begin to qualify as a loop – and with progressively frustrating results.

The answer to hook and loop’s inherent problem is to switch to durable and industrial strength dual lock fasteners that won’t snag or catch on anything. They also align perfectly every time and form an absolutely flawless bond until you’re ready to disengage them.

This fastener is 3M’s patented reclosable tape composed of adhesive-backed, mushroom-shaped stems that slide into position past each other to engage. A roll of tape essentially provides two equal-length, similarly-faced strips with rubber or acrylic-based backings that are temperature, moisture, and UV resistant and suitable for indoor or outdoor use.

What that means is if you need to affix an item for a long time, regardless of whether you’re adhering to an aluminium, steel, glass, ABS, PVC, PC, or powder coated substrate surface, you can rest assured that with 3m dual lock tape it’ll stay precisely where you’ve positioned it. No shifting, no wobbling, and no waiver until it’s disengaged.

Strength in numbers

What makes dual lock the veritable, all-purpose fastener, however, is that once those mushroom-shaped stems are engaged, a process which concludes with an audible “snap”, they form a bond that boasts five times the tensile strength of hook and loop designs.

These stems are still able to open and close thousands of times without losing any of that strength. That even makes this tape perfect for instant placement / frequent replacement situations where screws would have commonly been used, like:

· Quick release access panels;

· Displaying placards and signs; and,

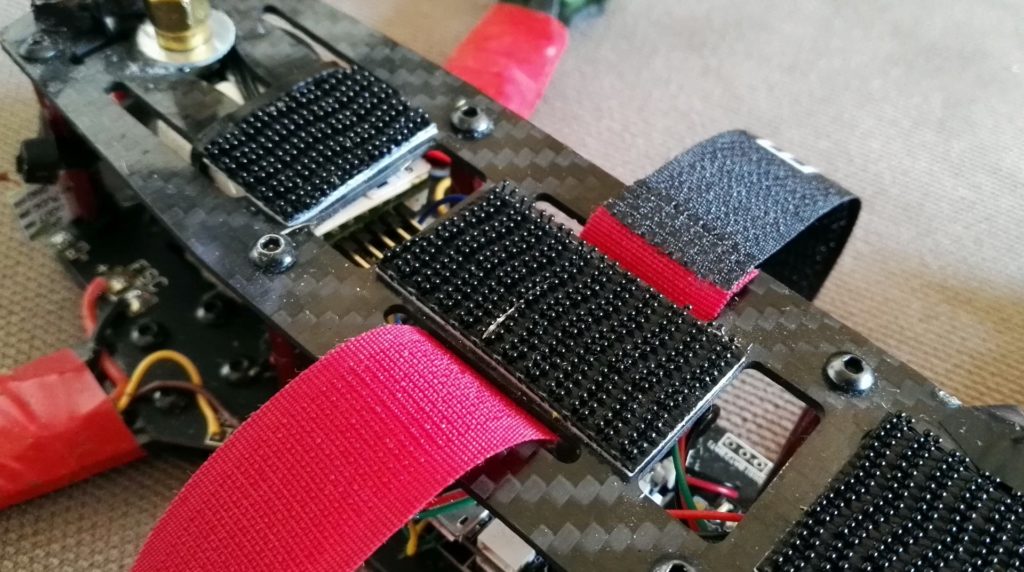

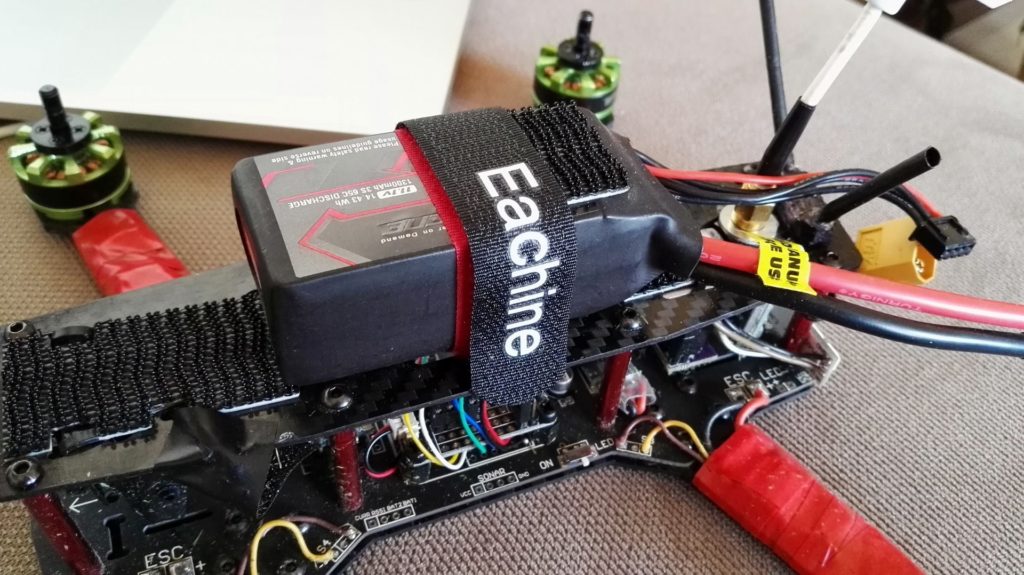

· Stabilizing electronic gear and assemblies.

Surprisingly, dual lock’s strength doesn’t come directly from the heavy-duty, polyolefin stems, but rather from their density. 3M’s 3 types of dual lock tape are identified by their stem-heads per square inch densities. With densities of 170, 250 and 400 stems per in² (respectively 26, 39 and 62 stems per cm²), the strength of the bonds can be varied by mating differing densities of tape, and by applying the tape over smaller or larger surface areas.

Whenever possible, however, dissimilar densities should be used together to ensure maximum contact across the mating area, and the more rigid the substrate, the stronger the bond. So how does that effect tensile strength? The following matches will typically yield the following results:

Mating 170 with 250

With an engaged tensile strength of 13 lb/in² and disengaging strength of 27 lb/in², this pairing forms a reasonably strong bond.

Mating 170 with 400, or 250 with 250

With an engaged tensile strength of, respectively, 21 and 22 lb/in² and disengaging strength of 43 lb/in², these pairings form a bond that are comparable to each other in strength, with roughly 60% greater tensile stronger than mating 170 with 250.

Mating 250 with 400

With an engaged tensile strength of 31 lb/in² and disengaging strength of 60 lb/in², this pairing forms the strongest bond, with almost 3 times the tensile strength of mating 170 with 250. Interestingly, 3M advises against mating 170 with 170 and 400 with 400. With 170, the stem pattern doesn’t line up well with itself, creating a situation that’s analogous with hook and loop style fasteners not fully fastening.

With 400, the exact oppose is apparent: the extreme density of mating 400 with itself would not only be extremely difficult to engage but virtually impossible to disengage. Of course, there are other factors that can impact the strength of dual lock fasteners too, such as:

· Excessive vibration of the substrate,

· Misaligned mating parts or uneven mating surfaces,

· Weak mating angles similar to peel or cleavage states.

By employing the same precautions that should be exercised when using any other touch-type fastener – hook and loop or otherwise – dual locks will not only outperform them, but will do it consistently for years to come.

The conclusion

At the end of the day, reclosable fasteners are indeed one of the greatest inventions over the last century. In any of their various forms, they’ve been used everywhere – from handbags to the space shuttle – but they’ve never shown an industrial strength capacity.

3M’s patented dual lock fastener is the first to possess this capacity: combining incomparable tensile strength with the ability to fine-tune that strength simply by changing the density of the fastener.

In other words, it’s a fastener that’s in a league all its own. When you’re in the market for touch-type fastener, don’t hesitate to look at 3M’s reclosable solution. Once you start using it, you’re guaranteed to discover even more uses for it.