If there’s one machine that industrial plants, schools and hobbyists all benefit alike, it’s a laser cutter. Laser cutting is a highly precise method of cutting or engraving a variety of materials ranging from plastic to cardboard, paper, wood, metal, glass, acrylic, leather and more. While conventional mechanical cutting works well, laser cutters are considered the superior option for many reasons.

For starters, the cuts made by a laser are microscopically precise and do not require a lot of time to make. And because the cut is made by a laser beam, there’s no physical contact between the machine and what’s being cut, eliminating the risk of material contamination. This way, the same machine can be used on a variety of different materials, without needing to be cleaned between uses. And since the laser uses a highly focused spot, the material is subjected to less heat, thus reducing the chances of warping. Due to the precision cuts, the final result requires little to no modifications, which significantly speeds up the manufacturing process.

Additionally, as opposed to mechanical cutters, laser cutters are incredibly easy to operate, which is why they can be used by skilled engineers as well as artists, student and amateur makers. You don’t have to have any special graphic design background either. One popular laser cutter for home and classroom use is the Darkly Labs Emblaser, which allows you to create your design in any graphics program, whether it be Adobe Illustrator, Corel Draw, Photoshop or Solidworks – it’s entirely your choice.

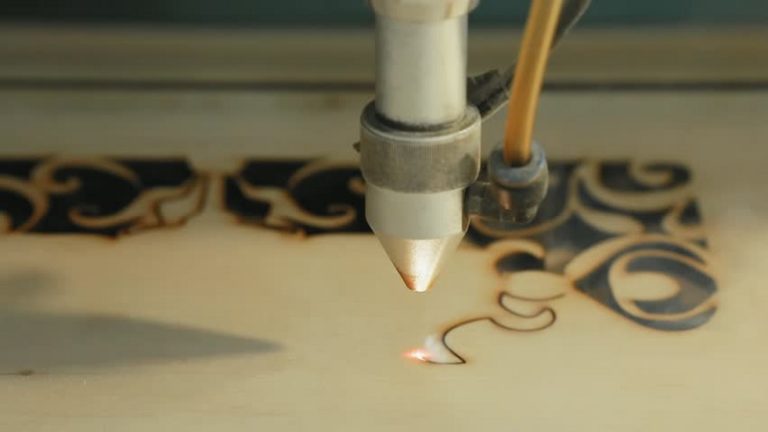

Aside from the general ease of operation, you’d be surprised how many creative ways there are to use a laser cutter. For one, laser cutters are not restricted by physical boundaries like regular cutters are. Because the machine doesn’t need to touch the part being cut, you can move it in all directions to cut or etch intricate shapes and design. The process itself is as easy as drawing on a regular sheet of paper. Because of this, there are no limits to the objects you can produce – whether it’s jewellery, business cards, toys or sculptures – there are countless ways you can unleash your creativity.

In a nutshell, laser cutters definitely have a number of benefits over standard ones. But they are a major investment, so if you do plan to buy one, there are some things you need to consider. Like for instance, what will you use the machine for? CO2 laser cutters are the highest-power continuous wave lasers available on the market. Because of their power, they are most suitable for industrial applications. On the other hand, there are also desktop laser cutters such as the Darkly Labs Emblaser which is easy and safe to use in any environment due to being combined with an air filtration unit.