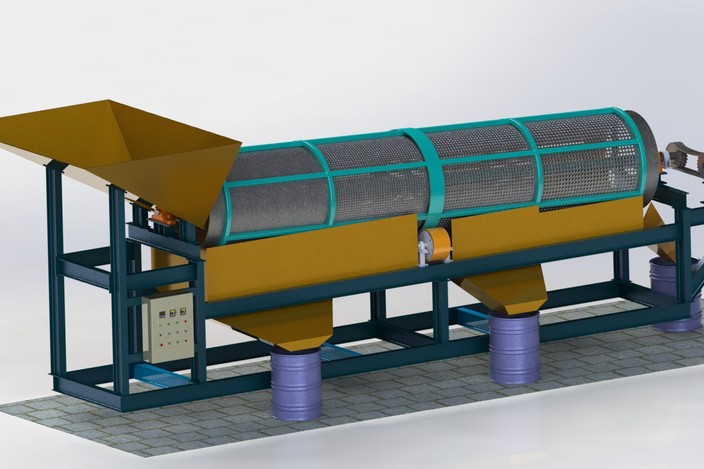

Some would say that the trommel is generally a big drum with holes that only spins, but the design of the trommel screens hides much more. First of all, let’s clear out what trommel screen is: it is an important piece of screening equipment, used mostly in the solid-waste and mineral processing industries. The trommel screen is composed of a rotating cylindrical drum which effectively separates materials by their size. The material that is fed into the trommel screen passes through a series of screes which contain specific hole sizes. The oversize particles are being discharged from one end of the drum. Many contractors use trommel screens without understanding their unique design. When choosing a trommel screen, the factors stated bellow must be closely considered.

A trommel screen is needed where the drum angle is level, or when a slight slope requires a drum with internal screw. To move the material through the drum, the leveled trommel screen requires an internal spiral. Internal lifter bars help the separating process by providing drop and lift action which causes the material to easily move through the drum. Without these lifter bars, the trommel screen operates slowly and provides less efficient screening. However, for screening heavy materials, the trommel screens do not include internal lifter bars, because their dropping will damage the trommel screen significantly.

Many trommel screens have a perforated plate screen. When this plate is welded and rolled to form the drum, the trommel screen is much stronger than the typical steel structure with mesh attached. The welded and rolled drums have holes so they can be less prone to damages from the heavier objects. Also, it is easier to maintain, mainly because it does not include ridges. Without ridges, the wear in plate screens is significantly reduced. The thickness of the rolled steel is determined by the impact of the materials. Thicker drums supposedly have bigger wear life.

Trommel screens feature various drive systems. One common drive system is the friction drive that comes from the supporting wheels. The decision of drive system is strictly based on the available friction through the support wheels for performing the tasks. Lastly, the drum speed of the trommel screens can be adjusted depending on the operator requirements.