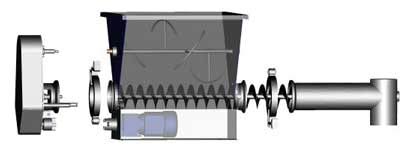

The screw feeders are special devices or machines which are used for a variety of material handling applications. Consisted of a helicoidal surface fitted on a shaft that rotates inside a fixed tube, a standard screw feeder comes with different openings for handling different materials.

Usually short in length, the screw feeders are designed to adjust the volumetric rate of different materials from a bin, hopper or a storage unit. Available in a wide range of designs and with different features, each screw feeder is used for specific application.

Multiple Diameter Feeder

The multiple diameter feeder is a combination of a feeder and a conveyor with variable physical dimensions. While the small diameter end operates at a full cross sectional load, the larger cross sectional loads are controlled at a maximum rate.

Short Pitch Feeder

Also a combination of feeder and conveyor, the short pitch feeder can handle full cross sectional loads efficiently.

Variable Pitch Twin-Tapered Feeder

This screw feeder is commonly used to unload bins of hoppers at a controlled rate. The feed opening is specifically designed to prevent material bridging. As a result, the chances for material bridging or spoiling are significantly reduced.

Live Bottom Feeder

Composed of several feeder screws at the bottom of the bin, this screw feeder is used for straight sided bins and offers great advantage when used for materials that tend to pack or bridge easily.

Screw Feeder Capacity

The capacity of a typical screw feeder varies depending on the variation of the materials in the bin and their characteristics.

Screw Feeder Speed

For maximum efficiency, the screw feeder must be operated at lower speed than the standard screw conveyors.

The design of a typical screw feeder depends on the material class and physical characteristics, the required capacity, material factor ‘F’, the material weight resting on the feeder screw, and the dimensions of the openings.

When looking for a screw feeder on the market, it is highly recommended to consult with a specialist who can help you choose the tight screw feeder for your application. This will ensure high efficiency, safe operation and increased profitability.